BGX-2-1D

The Monoblock filling and capping machine is a versatile and integrated solution that combines the functions of filling and capping into a single efficient system, streamlining the packaging process.

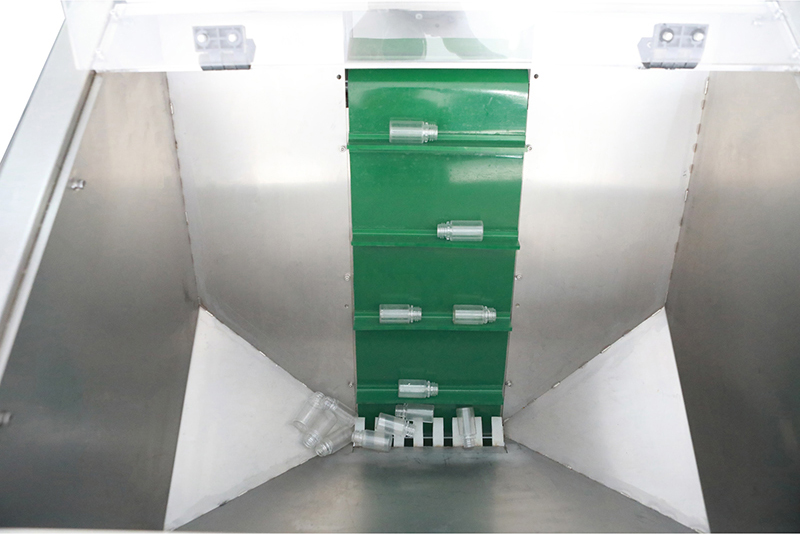

The equipment is Automatic monoblock bottle filling and capping machine equipment, which makes the high-viscosity filling and ordinary pressure filling into one. Under the high-viscosity mode, the machine adopts the cylinder to control filling head so that it can ensure the stability and precision; under the ordinary pressure filling mode, the filling part adopts fixed passageway parameters, and the machine realizes the different filling dose by controlling the filling time.

An Automatic Monoblock Bottle Filling and Capping Machine is an advanced industrial equipment designed to streamline the process of filling and capping bottles in a single integrated unit. This monoblock system combines both filling and capping functions, allowing for efficient and automated production of bottled products across various industries.

Advantages of the Automatic Monoblock Bottle Filling and Capping Machine:

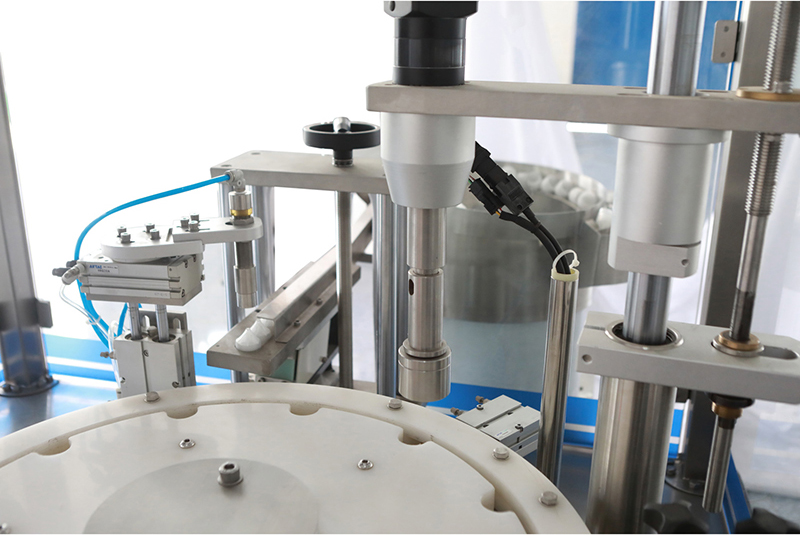

Integrated Efficiency: This machine combines two critical processes, filling and capping, in a single unit. This eliminates the need for separate machines, saving space and improving production line efficiency.

Consistent Quality: The monoblock design ensures that filling and capping processes are closely synchronized, resulting in consistent product quality and reducing the risk of errors.

Labor and Time Savings: Automation minimizes manual intervention, reducing labor requirements and increasing overall production speed.

Reduced Risk of Contamination: The closed-system design of the machine reduces the exposure of the product to external contaminants, ensuring product hygiene and safety.

Applications of the Automatic Monoblock Bottle Filling and Capping Machine:

This machine finds applications in a wide range of industries, including:

Beverage Production: Filling and capping bottles with liquids like water, juices, soft drinks, and alcoholic beverages.

Pharmaceuticals: Filling and capping bottles with medications, syrups, and liquid pharmaceutical products.

Personal Care: Packaging cosmetics, lotions, shampoos, and other liquid personal care products.

Key Features of the Automatic Monoblock Bottle Filling and Capping Machine:

Integrated Design: Combines filling and capping stations in a compact and synchronized manner.

Multiple Filling Methods: Can accommodate different filling techniques, such as volumetric filling or gravity filling, based on the product's properties.

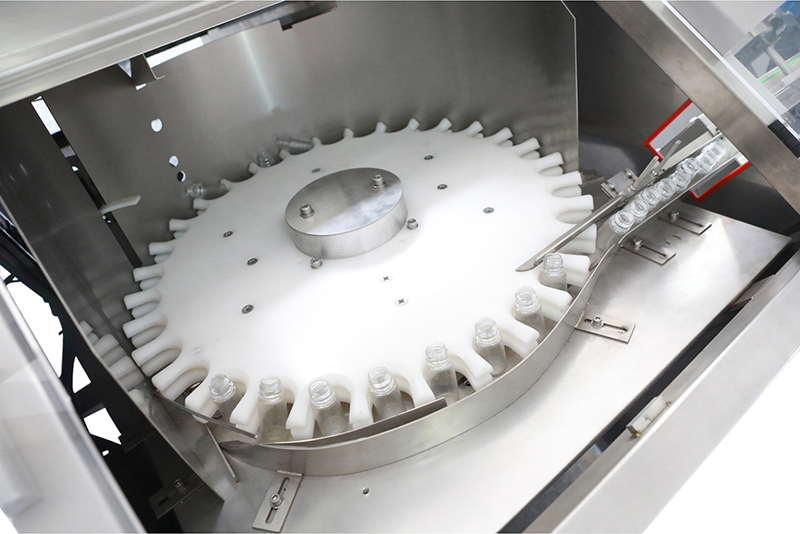

Adjustable Configuration: Easily adjustable to handle various bottle sizes, shapes, and cap types.

Quality Control Mechanisms: Often includes sensors and detectors to identify and reject improperly filled or capped bottles.

Types of Automatic Monoblock Bottle Filling and Capping Machines:

Rotary Monoblocks: Bottles are transferred through a circular arrangement of filling and capping stations.

Linear Monoblocks: Bottles move linearly through the integrated processes in a straight line.

Installation and Usage:

Installation involves integrating the machine into the production line, connecting utilities like power, air, and sometimes liquid sources. The machine is operated through a user-friendly interface, which allows operators to set parameters, monitor the process, and perform troubleshooting if needed.

For specific information on pricing, configuration models, delivery locations, and payment methods, kindly contact our customer service team.

the Automatic Monoblock Bottle Filling and Capping Machine offers an innovative solution for efficient and synchronized bottle packaging. Its integrated functionality, versatility, and time-saving features contribute to the optimization of the production process, meeting the demands of modern manufacturing standards.

0

0

Changzhou Bojun Packaging Machinery Co., Ltd. is located in Changzhou Jintan District Economic Development Zone, is an enterprise focusing on the research and development, production, sales and service of automated packaging equipment.

E-mail: bojunyin@126.com

Mobile: 0086-18018039235

Tel: 0086-0519-82555020

WhatsApp: +86-18018039235

Add: No.20-4 Kaiyuan Road, Jincheng Town, Jintan, Changzhou, Jiangsu Province, China