A powder filling line is a specialized automated system designed to efficiently fill various powdered products, such as spices, pharmaceuticals, food additives, and chemicals, into containers or packaging. This advanced production line streamlines the filling process, ensuring accurate measurements and reducing manual handling, thereby increasing productivity and maintaining product quality.

Function and Purpose: The primary purpose of a powder filling line is to precisely measure and fill powdered substances into containers or packaging, minimizing wastage and ensuring consistent product quantities. The line caters to the specific needs of industries dealing with powdered products, facilitating efficient and hygienic packaging on a large scale.

Characteristics and Applications: The powder filling line is characterized by its high-speed filling capabilities, accurate dosing mechanisms, and dust control features. It is capable of handling a wide range of powder densities, ensuring adaptability for different product types. Whether it's fine powders or granulated substances, the filling line ensures uniformity in every package.

The line finds applications in various industries, including food and beverage, pharmaceuticals, cosmetics, and chemical manufacturing. It enables these industries to meet the demands of consumers and efficiently package their powdered products for distribution and sale.

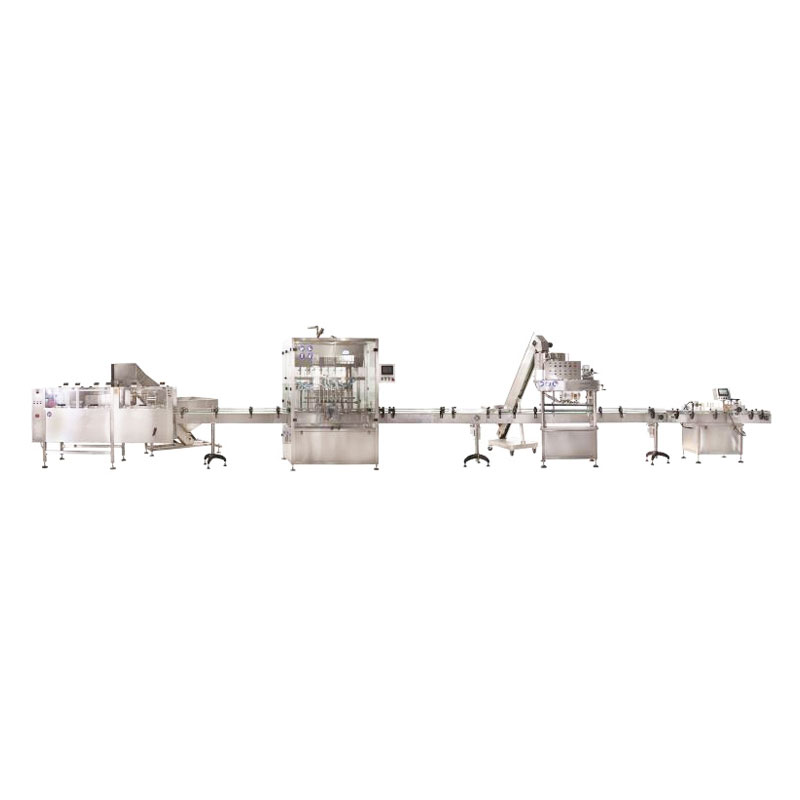

Components and Parts: A typical powder filling line consists of several essential devices and components, including:

Hopper: Stores the bulk powder to be filled into containers.

Auger Filler: Utilizes an auger screw to dispense precise amounts of powder into the containers.

Weighing System: Ensures accurate measurements and proper dosage control.

Conveyor System: Transports containers to different stations in the filling process.

Dust Collection Unit: Captures excess powder and prevents airborne particles.

Capping or Sealing Machine: Seals the filled containers, ensuring product safety and integrity.

Labeling Machine: Attaches product information and branding labels to the containers.

Usage Instructions: Operating a powder filling line requires skilled operators who are trained in machine handling, maintenance, and safety protocols. The process starts by setting up the machine, ensuring proper calibration, and adjusting the auger filler to the desired dosage. Containers are then fed into the line through the conveyor system, and the filled packages proceed to the capping and labeling stages. Regular maintenance and cleaning are essential to prevent cross-contamination and ensure the line's optimal performance.

In conclusion, the powder filling line plays a vital role in efficiently and accurately filling powdered products into containers for various industries. With its advanced features and wide-ranging applications, it contributes to streamlined production processes and consistent packaging, meeting the demands of modern manufacturing standards.