A beverage bottling line is a sophisticated and automated system designed to efficiently package beverages, such as soft drinks, juices, water, and alcoholic beverages, into bottles or containers. This specialized production line plays a crucial role in the beverage industry, ensuring the seamless and hygienic bottling of various beverages for mass distribution and consumption.

Function and Purpose: The primary purpose of a beverage bottling line is to streamline the packaging process, from filling the bottles with the beverage to capping and labeling them. By automating these tasks, the bottling line significantly improves production efficiency, reduces manual errors, and maintains product quality and consistency. This efficient system allows beverage manufacturers to meet the ever-increasing demand while adhering to strict hygiene and safety standards.

Characteristics and Applications: The beverage bottling line boasts several notable features, including high-speed filling capabilities, precision filling measurements, and state-of-the-art quality control systems. These lines can handle a wide range of bottle sizes and types, making them adaptable for different beverage products. Whether it's carbonated drinks, still beverages, or flavored waters, the bottling line can handle diverse formulations.

Additionally, the bottling line finds applications in both large-scale production facilities and smaller manufacturing plants. It is equally suitable for established beverage brands and emerging companies looking to scale up their production capacity.

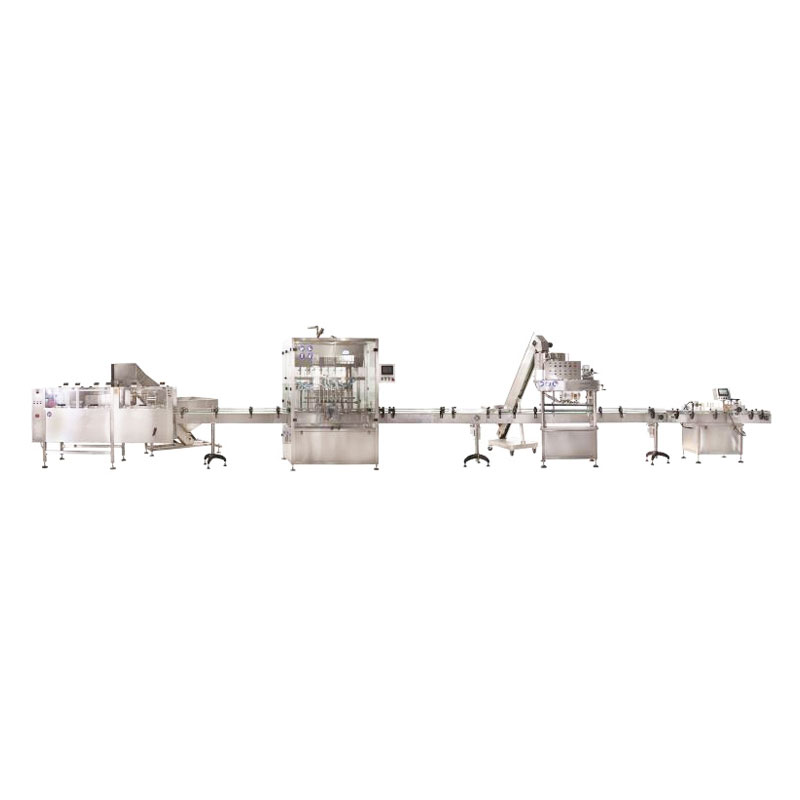

Components and Parts: The beverage bottling line comprises several key devices and components, each playing a critical role in the packaging process. These may include:

Bottle Unscrambler: Aligns and feeds empty bottles onto the production line.

Rinser: Cleans and sanitizes the bottles before filling to ensure hygiene.

Filler: Accurately fills the bottles with the beverage, using either volumetric or weight-based methods.

Capper: Securely applies caps or closures on the filled bottles.

Labeling Machine: Attaches labels with product information, branding, and regulatory details on the bottles.

Conveyor System: Transports the bottles between various stages of the bottling process.

Quality Control Stations: Inspects filled bottles for defects, leakage, and proper cap sealing.

Usage Instructions: Operating a beverage bottling line requires a team of trained technicians and operators. They oversee the entire process, monitor equipment performance, and address any issues that may arise during production. Proper maintenance is vital to ensure smooth functioning, avoid breakdowns, and uphold product quality.

In conclusion, the beverage bottling line plays a pivotal role in the beverage industry, enabling efficient and standardized packaging of various beverages. With its advanced features and adaptable nature, it caters to the needs of both established and emerging beverage manufacturers, ensuring a steady supply of refreshing drinks to consumers worldwide.