Beverage Filling Production Line: Efficient and Reliable Solution for Bottling Needs

A beverage filling production line is a sophisticated and automated system designed to fill and package beverages, such as water, soft drinks, juices, and alcoholic beverages, into bottles, cans, or other containers. This advanced production line plays a crucial role in the beverage industry, enabling efficient mass production and ensuring product consistency and quality.

The primary function of a beverage filling production line is to streamline the bottling process, significantly reducing human labor and minimizing the risk of contamination. It allows for high-speed filling, capping, labeling, and packaging, enhancing productivity and meeting the demands of a competitive market.

Key characteristics and applications of a beverage filling production line:

Precision Filling: The production line employs precise measuring and filling mechanisms to ensure accurate volumes of liquid in each container, minimizing wastage and maintaining uniformity in the final product.

Hygienic Design: Beverage filling production lines are constructed with stainless steel and other food-grade materials, making them easy to clean and ensuring compliance with strict hygiene standards.

Versatility: These production lines can accommodate a wide range of beverage types and container sizes, making them suitable for various product offerings.

Quality Control: Integrated sensors and monitoring systems allow real-time quality checks during the filling process, guaranteeing that only defect-free products reach the market.

Sustainable Packaging: Many modern beverage filling lines incorporate eco-friendly packaging options, reducing the industry's environmental footprint.

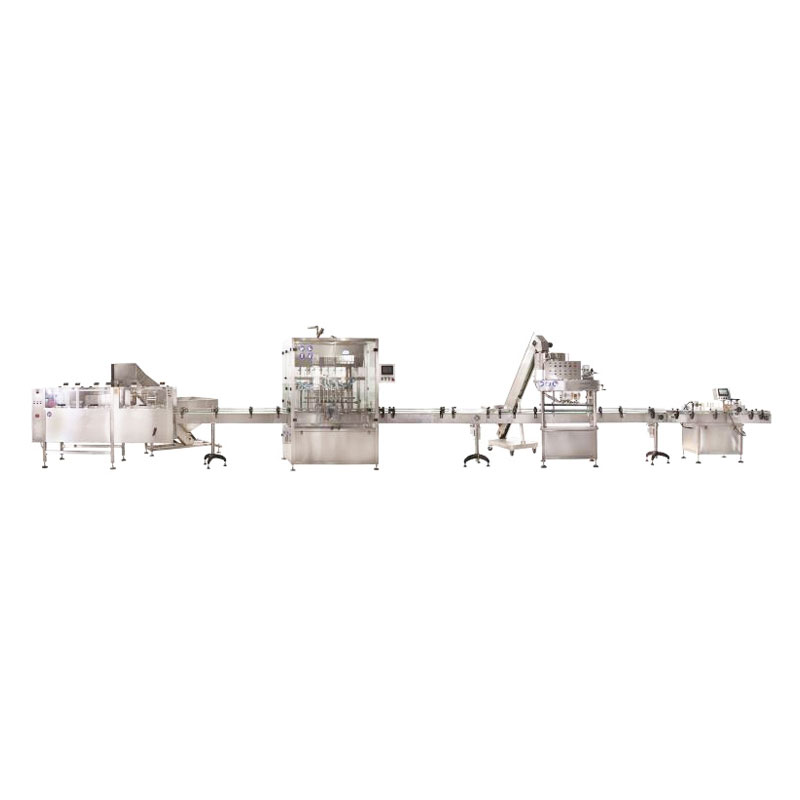

A beverage filling production line typically includes the following components and parts:

a. Conveyor Systems: Transport containers throughout the production process efficiently. b. Rinse and Sterilization Units: Thoroughly clean and sanitize bottles before filling. c. Filling Stations: Precisely fill bottles with the beverage. d. Capping Machines: Apply caps or lids securely to the filled containers. e. Labeling Machines: Attach product labels with accuracy and consistency. f. Packaging Machines: Prepare and package the filled containers for distribution.

Using a beverage filling production line involves the following steps:

Container Preparation: Bottles or cans are placed onto the conveyor system to begin the filling process.

Pre-Filling Rinse: Containers pass through rinse units to remove dust and debris.

Filling: The beverage is accurately dispensed into each container at the filling stations.

Capping: Caps or lids are applied to the filled containers to seal them securely.

Labeling: Product labels are automatically attached to the containers.

Packaging: The filled and labeled containers are packaged and prepared for shipping.

In conclusion, the beverage filling production line is a crucial asset for the beverage industry, allowing manufacturers to efficiently produce high-quality products in large quantities. Its precision, hygiene, and adaptability make it an indispensable tool for meeting the demands of consumers and maintaining a competitive edge in the market.